Name: Ilmberger

Address:

Website: www.ilmberger-carbon.com

European Manufacturer: Yes

ILMBERGER

Couldn't load pickup availability

ABE in Vorbereitung

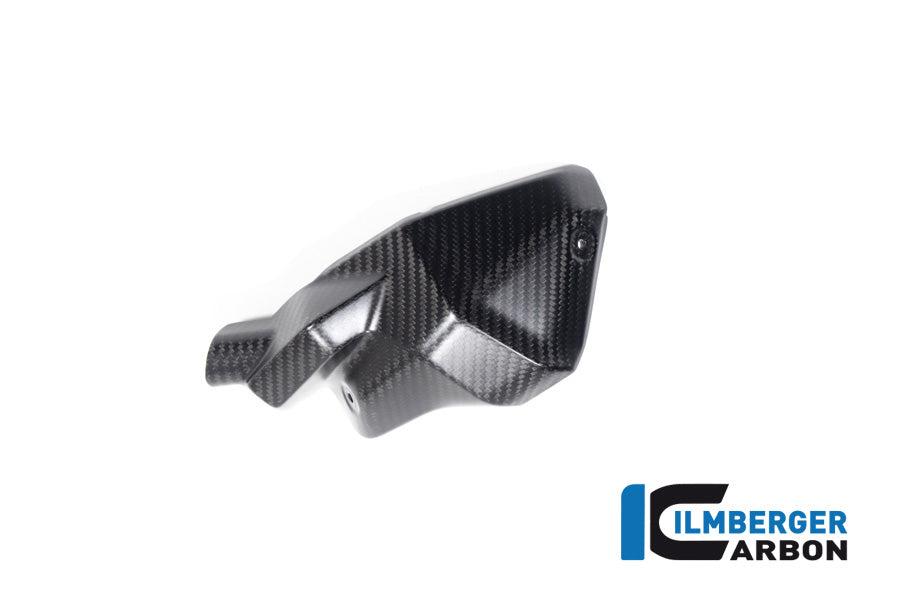

Die Carbon Einspritzdüsenabdeckung für die BMW R 1300 GS verleiht Ihrem Motorrad eine einzigartige, sportlich-luxuriöse Optik. Das Bauteil aus hochwertigem Carbon wird direkt auf den Zylindern des Boxermotors montiert und ist somit gut sichtbar. Die auffällige, exponierte Stelle des Carbonteils unterstreicht die edle Anmutung Ihres Motorrads und verleiht ihm eine persönliche Note.

Der Name Ilmberger steht für höchste Qualität und Innovation im Bereich der Carbonfertigung. Jedes Teil wird in unserer eigenen Produktion gefertigt, wobei wir auf speziell für Ilmberger entwickeltes Prepreg als Basismaterial setzen. Dieses wird in einem aufwendigen Verfahren im Autoklaven verarbeitet, was zahlreiche Vorteile bietet.

Prepreg, ein vorimprägniertes Carbongewebe, zeichnet sich durch eine gleichmäßige Harzverteilung, bei einem gleichzeitig hohen Faservolumengehalt aus. Dies führt zu einer maximalen Festigkeit und erhöht die Flexibilität der Bauteile. Durch die Verarbeitung im Autoklaven, einem Hochdruckofen, der unter kontrollierten Temperatur- und Druckbedingungen arbeitet, wird eine perfekte, gleichmäßige Aushärtung und eine makellose Oberfläche gewährleistet. Diese Methode verhindert Lufteinschlüsse im Material und sorgt für eine gleichbleibend hohe Qualität der Teile.

Unsere Carbonteile werden mit viel Erfahrung und Sorgfalt in Handarbeit laminiert, was eine gleichbleibende Faserausrichtung ohne Verzug ermöglicht. Nach dem Aushärten im Autoklaven werden die Kanten der Teile präzise per Roboter geschnitten, um eine perfekte Passform und höchste Qualität sicherzustellen.

Ein weltweit einzigartiger Schritt in der Produktion von Ilmberger ist die vollständige Kunststoffpulverbeschichtung aller Carbonteile. Diese Beschichtung schützt die Teile nicht nur vor Umwelteinflüssen, sondern verleiht ihnen auch einen unvergleichlichen Tiefeneffekt. Kein anderer Carbonhersteller bietet diese Art der Versiegelung an, die das Altern der Teile verhindert und ihre Lebensdauer erheblich verlängert. Weitere Informationen über die Kunststoffpulverbeschichtung finden Sie hier.

Die abschließende Klarlackschicht ist bei diesem Bauteil hochglänzend und sorgt für eine perfekte, glatte Oberfläche, die den luxuriös-sportlichen Look unserer Carbonteile weiter unterstreicht. Jedes Teil, das unsere Produktion verlässt, ist ein Meisterwerk der Technik und des Designs, das höchsten Ansprüchen gerecht wird.

Ilmberger ist nicht nur führender Hersteller von Carbonteilen für den Aftermarket, sondern auch anerkannter OEM-Produzent von namhaften Herstellern wie Ducati und BMW. Wir fertigen unter anderem Teile für BMW in der World Superbike Championship (WSBK), sowie für das BMW Werksteam in der Endurance World Championship (EWC), wo unsere Teile regelmäßig unter härtesten Bedingungen auf die Probe gestellt werden.

Die daraus gewonnene Expertise fließt in jedes unserer Produkte ein und verbessert so jedes einzelne Bauteil.

Die Fakten:

Produktion in eigener Fertigung nach ISO 9001

Mit ABE - keine zusätzliche Eintragung nötig

Verwendung von speziell für Ilmberger entwickeltem Prepreg

Fertigung im Autoklaven für maximale Festigkeit und perfekte Oberflächen

Einzigartige Kunststoffpulverbeschichtung zum Schutz und für einen besonderen Tiefeneffekt

Lamination in Handarbeit von Experten mit jahrelanger Erfahrung

Präziser Kantenschnitt per Roboter

Hochglänzende Klarlackschicht für eine makellose Oberfläche

Keine Alterung der Teile dank mehrschichtigem Schutz gegen UV-Licht

Lieferung in anbaufertigem Zustand

TÜV-zertifizierte Qualität

ABE in preparation

The Carbon fuel injector cover for the BMW R 1300 GS gives your motorcycle a unique, sporty-luxurious look. The high-quality carbon component is mounted directly on the cylinders of the boxer engine and is therefore clearly visible. The striking, exposed position of the carbon part emphasizes the noble appearance of your motorcycle and gives it a personal touch

The name Ilmberger stands for highest quality and innovation in carbon fiber manufacturing. Each part is produced in our own facility, where we use specially developed prepreg for Ilmberger as the base material. This is processed in an elaborate procedure in the autoclave, which offers numerous advantages.

Prepreg, a pre-impregnated carbon fabric, is characterized by an even resin distribution with a simultaneously high fiber volume content. This leads to maximum strength and increases the flexibility of the components. Processing in the autoclave, a high-pressure oven that operates under controlled temperature and pressure conditions, ensures perfect, uniform curing and a flawless surface. This method prevents air inclusions in the material and ensures consistently high quality of the parts.

Our carbon parts are laminated by hand with great experience and care, allowing for consistent fiber alignment without distortion. After curing in the autoclave, the edges of the parts are precisely cut by robot to ensure a perfect fit and highest quality.

A globally unique step in Ilmberger's production is the complete plastic powder coating of all carbon parts. This coating not only protects the parts from environmental influences but also gives them an incomparable depth effect. No other carbon manufacturer offers this type of sealing, which prevents the aging of the parts and significantly extends their lifespan. More information about the plastic powder coating can be found here.

The final clear coat layer on this component is high-gloss and ensures a perfect, smooth surface that further emphasizes the luxurious-sporty look of our carbon parts. Each part that leaves our production is a masterpiece of technology and design that meets the highest standards.

Ilmberger is not only a leading manufacturer of carbon parts for the aftermarket but also a recognized OEM producer for renowned manufacturers such as Ducati and BMW. Among other things, we manufacture parts for BMW in the World Superbike Championship (WSBK), as well as for the BMW factory team in the Endurance World Championship (EWC), where our parts are regularly put to the test under the toughest conditions. The expertise gained from this flows into each of our products, improving every single component.

The expertise gained from this flows into each of our products, improving every single component.

The facts:

Production in our own facility according to ISO 9001

Including ABE - Part is legal to use on the street

Use of prepreg specially developed for Ilmberger

Manufacturing in autoclave for maximum strength and perfect surfaces

Unique plastic powder coating for protection and a special depth effect

Hand lamination by experts with years of experience

Precise edge cutting by robot

High-gloss clear coat layer for a flawless surface

No aging of parts thanks to multi-layer protection against UV light

Delivery in ready-to-install condition

TÜV-certified quality